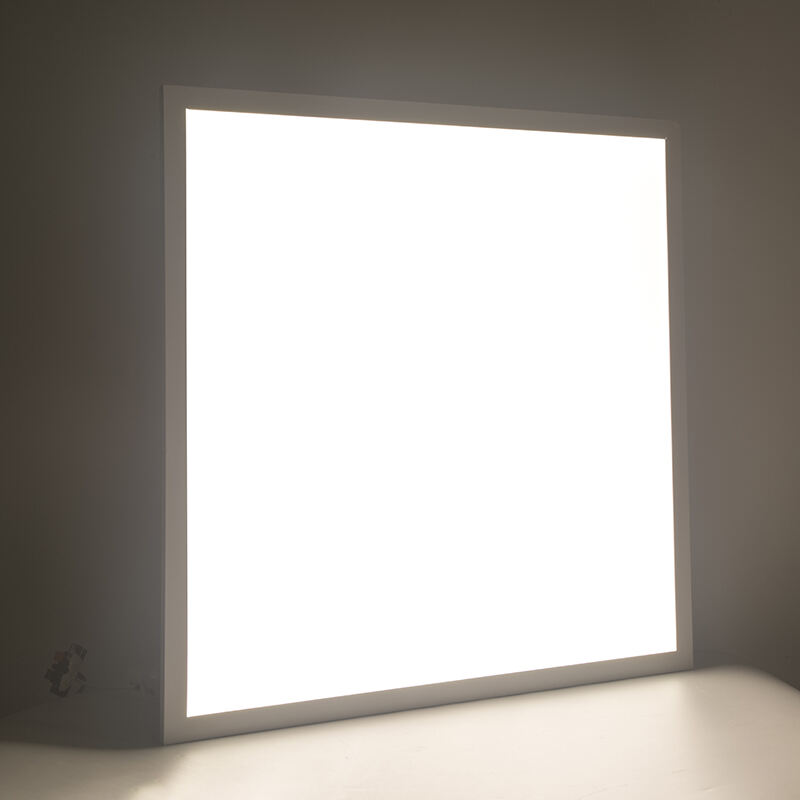

Light distribution plays a crucial role in creating comfortable and efficient indoor environments. LED panel light distribution has revolutionized how we illuminate spaces, offering superior uniformity and reduced glare compared to traditional lighting solutions. As businesses and homeowners increasingly adopt LED technology, understanding how to achieve optimal light spread becomes essential for creating productive and welcoming environments.

The heart of effective LED panel light distribution lies in the light guide plate (LGP). This sophisticated component transforms the concentrated light from LED chips into an even spread across the panel's surface. Modern LGPs utilize micro-etched patterns that precisely control how light travels and disperses, ensuring uniform illumination without hot spots or dark corners.

High-quality diffuser panels work in conjunction with the LGP to further enhance LED panel light distribution. These specialized materials scatter light particles evenly while maintaining optimal light transmission rates. The latest generation of diffuser materials can achieve up to 90% light transmission while eliminating glare and preventing visible LED dots.

Behind the LED chips, a reflective layer plays a vital role in maximizing light output and distribution efficiency. Advanced reflective materials can redirect up to 98% of light forward, ensuring minimal light loss and contributing to the overall uniformity of illumination. The careful engineering of this component directly impacts the panel's ability to deliver consistent brightness across its entire surface.

Achieving ideal LED panel light distribution requires careful consideration of installation parameters. The optimal mounting height typically ranges between 2.5 to 4 meters, depending on the panel's specifications and intended application. Proper spacing between panels should follow the manufacturer's recommendations, usually calculated as 1.5 times the mounting height for optimal overlap and elimination of dark zones.

The relationship between color temperature and light distribution significantly impacts the perceived quality of illumination. Cool white LEDs (5000K-6500K) typically provide better visibility and apparent brightness, while warm white options (2700K-3000K) create more comfortable atmospheres. The selected color temperature should align with the space's purpose while maintaining consistent LED panel light distribution.

Professional installation begins with thorough surface preparation. The mounting surface must be clean, level, and capable of supporting the panel's weight. Precise alignment during installation ensures optimal LED panel light distribution and prevents shadows or uneven illumination patterns. Using laser levels and proper mounting brackets helps achieve professional results.

Proper electrical installation ensures stable performance and longevity. Modern LED panels often incorporate dimming capabilities and smart control systems, which must be correctly configured to maintain even light distribution across all brightness levels. Advanced control systems can also compensate for ambient light conditions, automatically adjusting output to maintain consistent illumination throughout the day.

Maintaining optimal LED panel light distribution requires regular maintenance. Dust and debris can accumulate on panel surfaces, reducing light output and creating uneven illumination. Quarterly cleaning with appropriate anti-static materials helps preserve maximum efficiency and uniformity. Regular visual inspections can identify potential issues before they impact performance.

Modern LED panels often include sensors and monitoring capabilities that track performance metrics over time. Regular analysis of these data points helps identify variations in light output or distribution patterns. Making timely adjustments based on this information ensures consistent illumination quality and extends the panel's effective lifespan.

The future of LED panel light distribution lies in intelligent systems that automatically optimize performance. Advanced sensors and machine learning algorithms will continuously adjust output and distribution patterns based on real-time environmental conditions and user preferences. These smart systems will maximize energy efficiency while maintaining perfect illumination uniformity.

Ongoing research in materials science continues to improve LED panel components. New diffuser materials with enhanced light transmission properties and more efficient reflective coatings are under development. These innovations promise to further improve LED panel light distribution while reducing energy consumption and manufacturing costs.

To eliminate dark spots, ensure proper panel spacing during installation, verify the mounting height is within recommended ranges, and confirm the panels are correctly aligned. If dark spots persist, check for any physical obstructions or damage to the diffuser panel.

The ideal spacing typically follows the 1.5x rule - multiply the mounting height by 1.5 to determine optimal panel spacing. However, specific requirements may vary based on the panel's beam angle and manufacturer specifications.

Quality LED panels maintain consistent light distribution for 50,000 to 100,000 hours of operation. Regular maintenance and proper installation significantly impact long-term performance. Signs of uneven distribution may indicate the need for cleaning or potential component degradation.